Cast Basalt Liner & Fittings

MOQ : 1 Number

Cast Basalt Liner & Fittings Specification

- Tolerance

- 1 mm

- Feature

- Excellent wear and corrosion resistance, High compressive strength, Long service life

- Hardness

- 8 Mohs

- Material

- Cast Basalt

- Style

- Lined and Unlined

- Shape

- Round, Straight, Elbows, Tee, and Custom Shapes

- Temperature

- Up to 450C

- Application

- Coal Handling, Ash Handling, Mining, Pneumatic Conveying, Slurry Lines

- Surface Finish

- Smooth, Glossy

- Color

- Dark Grey-Black

- Length Range

- 250 mm to 1000 mm

- Internal Diameter

- 50 mm to 700 mm

- Density

- 2.8 3.0 g/cm

- Water Absorption

- < 0.02%

- Compressive Strength

- > 3000 kg/cm

About Cast Basalt Liner & Fittings

Experience the elite craftsmanship of Cast Basalt Liner & Fittings, a peerless solution designed for industries requiring spectacular durability and performance. With breathtaking compressive strength over 3000 kg/cm and extremely low water absorption (<0.02%), these scarce and hardwearing liners deliver personalised protection against wear and corrosion. Engineered with a smooth, glossy finish in dark grey-black, this range accommodates various applicationsstraight, round, elbows, tees, or custom shapes. Withstanding temperatures up to 450C, cast basalt components ensure an extended service life for your plant. Join a select group who demand only the best in quality and longevity.

Industrial Excellence for Heavy-Duty Applications

Cast Basalt Liner & Fittings are specifically engineered for plant use in coal and ash handling, mining, pneumatic conveying, and slurry lines. These robust fittings are designed for both lined and unlined installations, suiting diverse plant configurations. Simply orient and secure as per operational requirements to achieve optimum flow direction and efficiency. They guarantee flawless and uninterrupted material transportideal for demanding industrial environments where exceptional reliability is non-negotiable.

Sample Service, Certifications, and Reliable Supply

We offer exclusive sample handover by request, ensuring our clients experience first-hand the spectacular quality of our cast basalt solutions before making a charge. Certified for excellence, our elite liners meet stringent standards and come from a trusted exporter, manufacturer, and supplier in India. Our robust supply ability enables us to consistently fulfill even large orders, providing peace of mind for your ongoing projectswithout compromise in speed or quality.

Industrial Excellence for Heavy-Duty Applications

Cast Basalt Liner & Fittings are specifically engineered for plant use in coal and ash handling, mining, pneumatic conveying, and slurry lines. These robust fittings are designed for both lined and unlined installations, suiting diverse plant configurations. Simply orient and secure as per operational requirements to achieve optimum flow direction and efficiency. They guarantee flawless and uninterrupted material transportideal for demanding industrial environments where exceptional reliability is non-negotiable.

Sample Service, Certifications, and Reliable Supply

We offer exclusive sample handover by request, ensuring our clients experience first-hand the spectacular quality of our cast basalt solutions before making a charge. Certified for excellence, our elite liners meet stringent standards and come from a trusted exporter, manufacturer, and supplier in India. Our robust supply ability enables us to consistently fulfill even large orders, providing peace of mind for your ongoing projectswithout compromise in speed or quality.

FAQs of Cast Basalt Liner & Fittings:

Q: How can Cast Basalt Liner & Fittings benefit my plant operations?

A: Cast Basalt Liners and Fittings provide exceptional resistance to abrasion, wear, and corrosion, ensuring longer service life, reduced maintenance needs, and cost savings for your plants material handling systems.Q: What is the process for ordering personalised or custom-shaped fittings?

A: To order personalised or custom-shaped fittings, simply share your specifications or drawings with us. Our team will evaluate your requirements and produce spectacular, tailor-made components precisely engineered for your application.Q: When is it advisable to use cast basalt liners in industrial settings?

A: Cast Basalt Liners are best used when your operations demand high durabilitysuch as in coal or ash handling, mining, slurry piping, or pneumatic conveyingespecially where superior compressive strength and minimal water absorption are essential.Q: Where are samples available, and what certifications do you offer?

A: Samples can be handed over upon request, letting you inspect first-hand the mesmerising quality and finish. Our cast basalt liners are certified in accordance with stringent national and international standards, affirming their elite performance.Q: How should Cast Basalt Liner & Fittings be installed for optimal results?

A: Installation typically involves aligning the liner or fitting as per the required direction of use, followed by secure fastening in line with plant operating protocols. We recommend following best practices for joint sealing and support to maximise lifespan.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

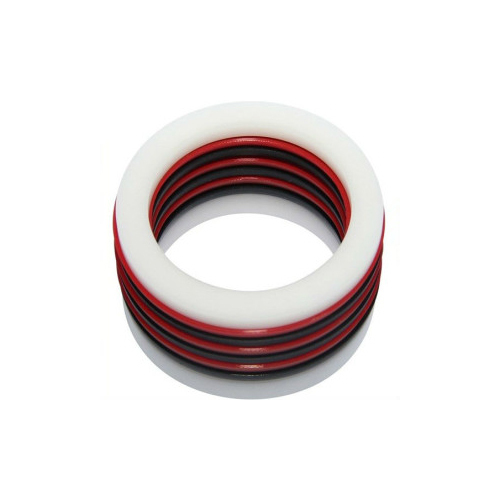

More Products in Rubber Seals Category

Hydraulic Chevron Packing

Price Range 300.00 - 1800.00 INR / Number

Minimum Order Quantity : 1 Number

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free